CAD/CAM Technology in Dental Labs: Benefits & Best Practices

The dental industry has evolved significantly with the introduction of CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) technology. This advanced digital workflow allows dental labs to create high-precision restorations with improved efficiency, accuracy, and consistency. In this blog, we will explore the benefits of CAD/CAM technology and share some best practices for dental labs looking to optimize their workflow.

Benefits of CAD/CAM Technology in Dental Labs

1. Unmatched Precision & Accuracy

CAD/CAM systems eliminate human error by utilizing digital scanning and automated milling. This results in restorations with superior fit and function, reducing the need for manual adjustments.

2. Faster Turnaround Time

Traditional methods require multiple appointments and lab processes. With CAD/CAM, restorations like crowns, bridges, and dentures can be designed and manufactured within hours instead of days.

3. Enhanced Consistency & Reproducibility

Digital designs allow labs to create identical restorations repeatedly with minimal variation, ensuring high-quality standards across all cases.

4. Cost-Effective Production

While the initial investment in CAD/CAM equipment is significant, it reduces labor costs and material waste in the long run. Additionally, labs can handle complex restorations in-house, cutting outsourcing costs.

5. Wider Material Selection

CAD/CAM technology enables the use of a variety of materials, including zirconia, lithium disilicate, CoCr, and resin, providing stronger, more aesthetic restorations.

6. Digital Storage & Improved Workflow

Digital impressions eliminate the need for physical molds, making patient data easy to store, retrieve, and modify. This enhances collaboration between dentists and labs.

Best Practices for CAD/CAM Implementation in Dental Labs

1. Invest in High-Quality Equipment

Choosing reliable scanners, milling machines, and sintering furnaces ensures long-term efficiency and precision. Brands like Roland DGShape, Shining 3D, and Exocad offer top-tier solutions.

2. Train Your Team

Having a well-trained team is crucial. Investing in CAD/CAM training programs ensures that technicians can maximize the potential of digital workflows.

3. Optimize Digital Workflow

Integrate scanners, CAD software, and milling machines seamlessly to minimize errors. Regular calibration of machines ensures optimal performance.

4. Choose the Right Materials

Selecting the appropriate material based on case requirements is essential for durability and aesthetics. For example, zirconia is ideal for crowns, while CoCr works well for implant frameworks.

5. Maintain Your Equipment Regularly

Routine maintenance of scanners, mills, and furnaces prevents unexpected breakdowns and extends equipment lifespan.

6. Stay Updated with Industry Trends

Dental technology is constantly evolving. Attending dental trade shows, webinars, and workshops helps labs stay ahead of advancements in CAD/CAM dentistry.

Conclusion

CAD/CAM technology has revolutionized dental labs by enhancing efficiency, precision, and profitability. By adopting best practices, dental labs can optimize their digital workflows and deliver superior restorations to dentists and patients alike.

Are you ready to upgrade your dental lab with CAD/CAM technology? Contact Agkem today to explore our cutting-edge digital dentistry solutions!

📞 +91 9599001079

🌐 www.agkem.com

Other Posts

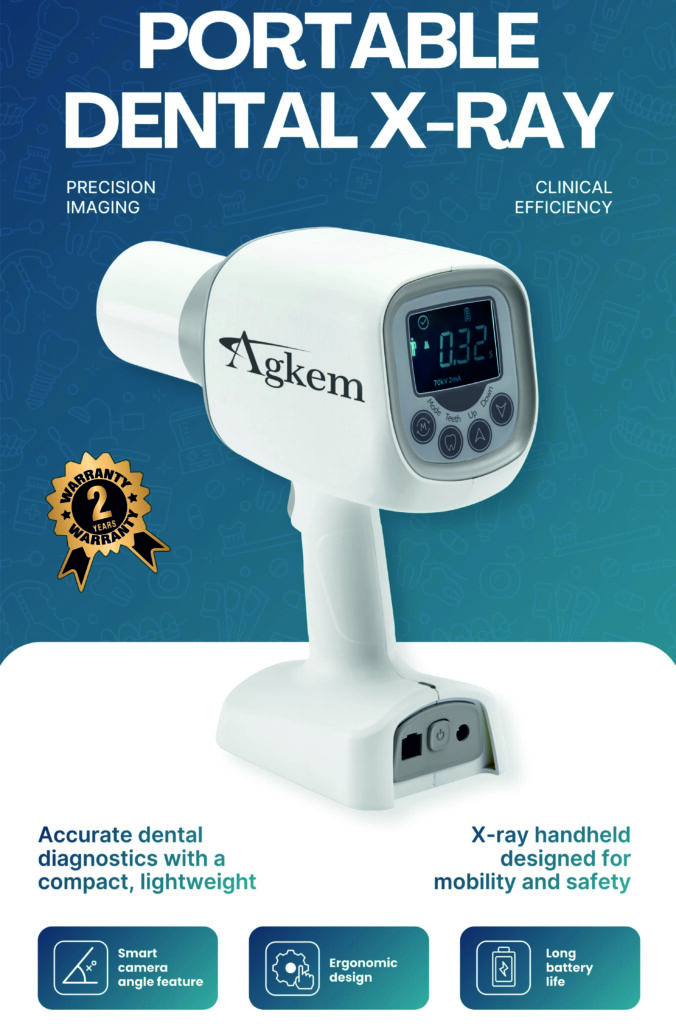

Agkem Portable Dental X-Ray: Precision Imaging with Complete Mobility

🦷 “Agkem Portable Dental X-Ray: Precision Imaging with Complete Mobility” Agkem Impex Modern dentistry demands speed, accuracy, and patient comfort....

The Science Behind a Bright Smile: Why Dental Cleanings Matter More Than You Think

🦷 “Healthy Gums, Happy Life: The Real Benefits of Professional Teeth Cleaning” Agkem Impex A bright, confident smile isn’t just...

The Role of 3D Printing in Digital Dentistry and Implantology

The Role of 3D Printing in Digital Dentistry and Implantology Agkem Impex The dental industry has entered a new era...