- Ultra-bright coatings of previously unattained lightness

- High plating efficiency

- Good covering power

- Excellent throwing power

- Suitable for rack and barrel

-

These plants are made up of :

These plants are made up of :- Polypropylene hood to be connected to a fume scrubber. Designed to the recover any acid losses.

- PPl tumbler

- PPl tray where two 100 lt containers for HCl and HNO3 acids are stored.

- 2 Filter units on wheels with a compressed air diaphragm pump to transfer the solutions.

- Cementation unit.

- No. 1 Control panel

-

• Resistor holding device; • Grid with collection tray and wax draining hose; • External lower tank for wax collection and cooling; • Exhaust hose for fumes with adjustable valve; • This structure can be entirely covered with panels and insulated by means of die-bent or rigid ceramic fiber; • PLC for the time-temperature parameters control with fully automatic programmable cycles; • Possibility to visualize the set programs during the working cycle (timer, set-point, temperature, working cycle number, step number); • Safety thermo-regulator.

• Resistor holding device; • Grid with collection tray and wax draining hose; • External lower tank for wax collection and cooling; • Exhaust hose for fumes with adjustable valve; • This structure can be entirely covered with panels and insulated by means of die-bent or rigid ceramic fiber; • PLC for the time-temperature parameters control with fully automatic programmable cycles; • Possibility to visualize the set programs during the working cycle (timer, set-point, temperature, working cycle number, step number); • Safety thermo-regulator. -

The new FIM/MCE vacuum casting furnace is used to produce casted jewellery as well as ingots or sheet. It is a combination of the most advanced casting technology and italimpianti Orafi’s 40 years experience in the goldmith industry. The unit has been designed to be user-friendly, facilitating the casting process and reducing all manual operations to a minimum, eliminating any possible man-made errors.

The new FIM/MCE vacuum casting furnace is used to produce casted jewellery as well as ingots or sheet. It is a combination of the most advanced casting technology and italimpianti Orafi’s 40 years experience in the goldmith industry. The unit has been designed to be user-friendly, facilitating the casting process and reducing all manual operations to a minimum, eliminating any possible man-made errors. -

APL Latex Examination Gloves are lightly dusted with Adsorbable Corn-Starch Powder with High Tear Resistance. These are manufactured from natural rubber latex. The gloves have straight fingers and are ambidextrous for a comfortable fit. These gloves are specially designed for conducting examinations, diagnosis and are safe for handling contaminated instruments. Uncompromised quality control ensures that each glove provides maximum protection against infections while providing superior comfort. High-quality antioxidants are added to increase shelf life.

APL Latex Examination Gloves are lightly dusted with Adsorbable Corn-Starch Powder with High Tear Resistance. These are manufactured from natural rubber latex. The gloves have straight fingers and are ambidextrous for a comfortable fit. These gloves are specially designed for conducting examinations, diagnosis and are safe for handling contaminated instruments. Uncompromised quality control ensures that each glove provides maximum protection against infections while providing superior comfort. High-quality antioxidants are added to increase shelf life. -

- Non-Powdered.

- Ambidextrous and straight fingers.

- Textured Softness provides superior comfort and natural fit.

- Designed especially for latex allergy sufferers

- Durable Sturdy boxes increasing the shelf life of Gloves Boxes.

- High Tear resistance.

- Protection from unwanted or dangerous substances during examination.

-

APL Latex Examination Gloves are lightly dusted with Adsorbable Corn-Starch Powder with High Tear Resistance. These are manufactured from natural rubber latex. The gloves have straight fingers and are ambidextrous for a comfortable fit. These gloves are specially designed for conducting examinations, diagnosis and are safe for handling contaminated instruments. Uncompromised quality control ensures that each glove provides maximum protection against infections while providing superior comfort. High-quality antioxidants are added to increase shelf life.

APL Latex Examination Gloves are lightly dusted with Adsorbable Corn-Starch Powder with High Tear Resistance. These are manufactured from natural rubber latex. The gloves have straight fingers and are ambidextrous for a comfortable fit. These gloves are specially designed for conducting examinations, diagnosis and are safe for handling contaminated instruments. Uncompromised quality control ensures that each glove provides maximum protection against infections while providing superior comfort. High-quality antioxidants are added to increase shelf life. -

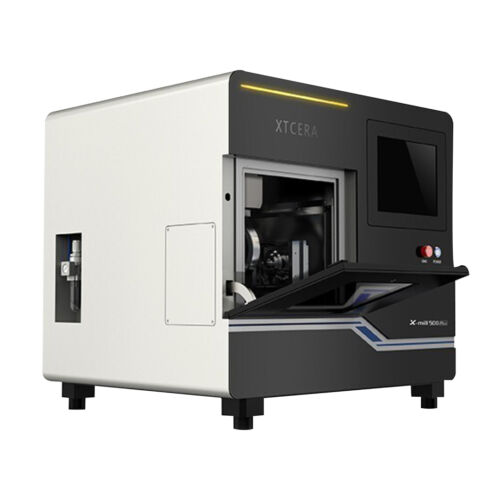

“ALL IN ONE”

The X-mill 600 is a detail oriented powerful 5 axis simultaneous milling machine with a B axis rotation range up to ±40°! Precision is provided with one-micron of repeatability for milling, grinding and drilling of implant bars, implant bridges and abutments. The 2.7kW spindle provides the ruggedness and durability to mill through the toughest geometries and materials while providing longevity. -

This product is sold in packs of 2.5 Kg The specific formulation of zinc-based soldering powders prevents the formation of surface oxide and reinforces the soldered link. A specific range of alloys for the investment casting containing deoxidizers to ensure the minimum loss, high fluidity during the casting, and extreme brilliance at the end of the process.

This product is sold in packs of 2.5 Kg The specific formulation of zinc-based soldering powders prevents the formation of surface oxide and reinforces the soldered link. A specific range of alloys for the investment casting containing deoxidizers to ensure the minimum loss, high fluidity during the casting, and extreme brilliance at the end of the process.