-

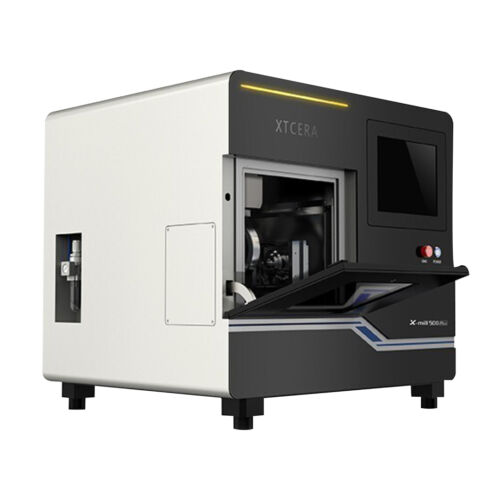

“ALL IN ONE”

The X-mill 600 is a detail oriented powerful 5 axis simultaneous milling machine with a B axis rotation range up to ±40°! Precision is provided with one-micron of repeatability for milling, grinding and drilling of implant bars, implant bridges and abutments. The 2.7kW spindle provides the ruggedness and durability to mill through the toughest geometries and materials while providing longevity. -

FAST & EASY DIAGNOSTIC IMAGES

- CMOS Technology

- Unique Size 1.5 Extra active area 34%

- High Comfortable: Cut Corners & Rounded Edges.

- Fast Data Transfer: Direct USB Connecter.

- Water & Dust Proof: Hermatically Sealed.

- Higher Image Resolution: 17lp/mm

- Fast Work Flow: EzDent-i Viewer Software

- 2 in 1 Consultation Tool: EzCodi Consult Software

- Your Total Peace of Mind: 5 Year Warranty.

-

The new FIM/MCE vacuum casting furnace is used to produce casted jewellery as well as ingots or sheet. It is a combination of the most advanced casting technology and italimpianti Orafi’s 40 years experience in the goldmith industry. The unit has been designed to be user-friendly, facilitating the casting process and reducing all manual operations to a minimum, eliminating any possible man-made errors.

The new FIM/MCE vacuum casting furnace is used to produce casted jewellery as well as ingots or sheet. It is a combination of the most advanced casting technology and italimpianti Orafi’s 40 years experience in the goldmith industry. The unit has been designed to be user-friendly, facilitating the casting process and reducing all manual operations to a minimum, eliminating any possible man-made errors.