-

“ALL IN ONE”

The X-mill 600 is a detail oriented powerful 5 axis simultaneous milling machine with a B axis rotation range up to ±40°! Precision is provided with one-micron of repeatability for milling, grinding and drilling of implant bars, implant bridges and abutments. The 2.7kW spindle provides the ruggedness and durability to mill through the toughest geometries and materials while providing longevity. -

Dual Mode Machine For Easy Powder Switching

Dual Mode Machine For Easy Powder Switching- Building Volume120*70mm,130 copings/batch, 10-12 RPD frames/batch, 130 copings/3.5-4.5 hours, 10 RPD frames/3-3.5 hours.

- Dual-mode printer supports Cobalt-Chromium and Titanium, and the switching time is only 45 minutes.

- Easy to start with Cobalt-Chromium mode and be able to upgrade to dual-mode later on.

- Equipped with glove box and built-in cleaner to implement closed powder cleaning and to avoid harmful dust.

- Proven stability in domestic and global market.

-

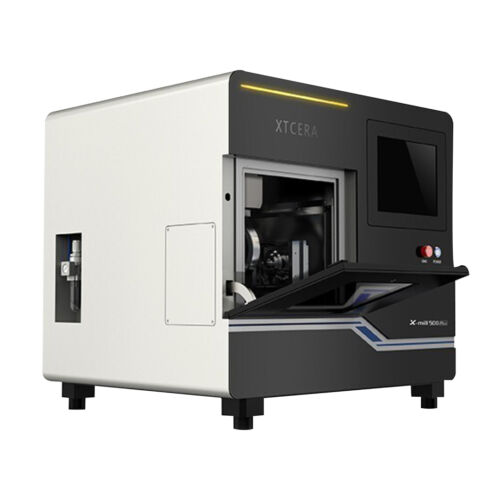

The industry’s best dental mill just got better with an all-new redesigned, upgraded spindle with 1.9× the gripping power for increased milling efficiency, expanded tool and material capabilities, and Intelligent Tool Control (ITC) • Precision 5-axis milling of zirconia, wax, PMMA, composite resin, glass fiber reinforced resin, pre-sintered chromium cobalt, and more • 15-station Automatic Tool Control and Intelligent Tool Control for uninterrupted milling operation

The industry’s best dental mill just got better with an all-new redesigned, upgraded spindle with 1.9× the gripping power for increased milling efficiency, expanded tool and material capabilities, and Intelligent Tool Control (ITC) • Precision 5-axis milling of zirconia, wax, PMMA, composite resin, glass fiber reinforced resin, pre-sintered chromium cobalt, and more • 15-station Automatic Tool Control and Intelligent Tool Control for uninterrupted milling operation -

• Increase productivity overnight with an automatic disc changing mill that offers 24-hour operation • Precision 5-axis milling of zirconia, wax, PMMA, composite resin, glass fiber reinforced resin, composite resin, pre-sintered chromium cobalt, and more • A 15-station Automatic Tool Changer for fast, efficient milling

• Increase productivity overnight with an automatic disc changing mill that offers 24-hour operation • Precision 5-axis milling of zirconia, wax, PMMA, composite resin, glass fiber reinforced resin, composite resin, pre-sintered chromium cobalt, and more • A 15-station Automatic Tool Changer for fast, efficient milling