-

A compact condenser designed for easy and reliable porcelain condensation during porcelain veneering of all-ceramic and metal-based restorations. Use of high frequency micro vibrations enhance condensation and ensure that the micro-fine particles are densely packed to prevent deformation of the layer structure.

A compact condenser designed for easy and reliable porcelain condensation during porcelain veneering of all-ceramic and metal-based restorations. Use of high frequency micro vibrations enhance condensation and ensure that the micro-fine particles are densely packed to prevent deformation of the layer structure. -

Light-curing micro-hybrid composite with a ceramic portion of more than 73 % micro-fine ceramic. The composition supported by a filling organic polymer matrix strengthens the homogeneous structure and gives Ceramage ceramic-like properties. The material is applied for metal-supported as well as metal-free anterior and posterior restorations.

Light-curing micro-hybrid composite with a ceramic portion of more than 73 % micro-fine ceramic. The composition supported by a filling organic polymer matrix strengthens the homogeneous structure and gives Ceramage ceramic-like properties. The material is applied for metal-supported as well as metal-free anterior and posterior restorations. -

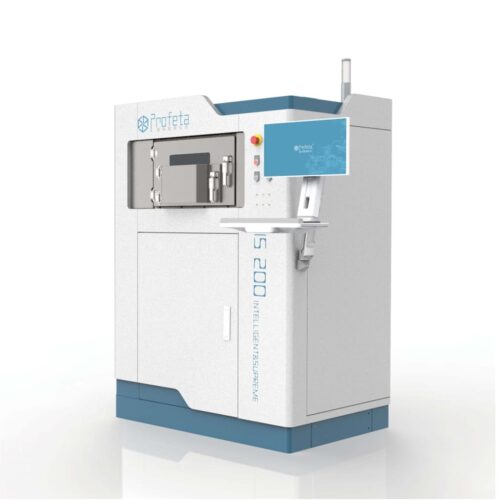

Dual Mode Machine For Easy Powder Switching

Dual Mode Machine For Easy Powder Switching- Building Volume120*70mm,130 copings/batch, 10-12 RPD frames/batch, 130 copings/3.5-4.5 hours, 10 RPD frames/3-3.5 hours.

- Dual-mode printer supports Cobalt-Chromium and Titanium, and the switching time is only 45 minutes.

- Easy to start with Cobalt-Chromium mode and be able to upgrade to dual-mode later on.

- Equipped with glove box and built-in cleaner to implement closed powder cleaning and to avoid harmful dust.

- Proven stability in domestic and global market.

-

- High-end machine with advanced algorithm and components brings the fastest printing speed (4.5-5.5hrs for 400 copings/36 RPD frames).

- The building volume (250*180*70mm) brings the highest volume per batch and reduces times of operations by 50%.

- The highest powder utilization (500-600 copings or 50-60 RPD frames/kg of powder).

-

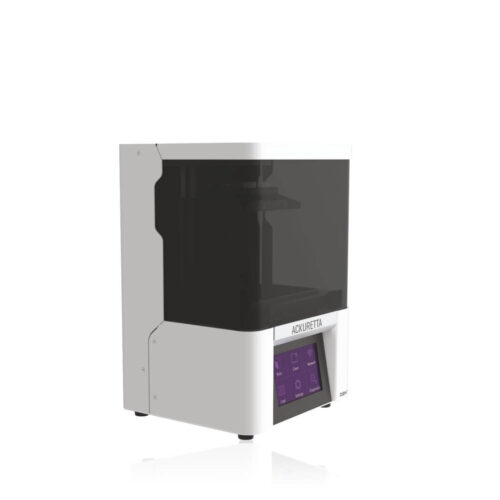

DENTIQ is a highly precise chairside 3D printer designed to provide an intuitive experience for every type of user. It offers a simple learning curve for beginners while providing the finer accuracy and consistency professionals desire. Remote diagnostics for machine repair, easy component replacement, built-in clean vat function, and warranty confidence makes owning DENTIQ effortless and rewarding. + Auto-calibration and 100+ precalibrated materials. + Plug & play, ready to use out of the box + 47-micron pixels finer accuracy and consistency + Ideal for chairside use and same-day dentistry + Premium ownership experience after purchase

DENTIQ is a highly precise chairside 3D printer designed to provide an intuitive experience for every type of user. It offers a simple learning curve for beginners while providing the finer accuracy and consistency professionals desire. Remote diagnostics for machine repair, easy component replacement, built-in clean vat function, and warranty confidence makes owning DENTIQ effortless and rewarding. + Auto-calibration and 100+ precalibrated materials. + Plug & play, ready to use out of the box + 47-micron pixels finer accuracy and consistency + Ideal for chairside use and same-day dentistry + Premium ownership experience after purchase