STAR SHT super-high translucency, apply to anterior .

SIZE:-

SHT 98*10mm 98*12mm 98*14mm 98*16mm 98*18mm 98*20mm 98*22mm 98*25mm

-

Light-curing micro-hybrid composite with a ceramic portion of more than 73 % micro-fine ceramic. The composition supported by a filling organic polymer matrix strengthens the homogeneous structure and gives Ceramage ceramic-like properties. The material is applied for metal-supported as well as metal-free anterior and posterior restorations.

Light-curing micro-hybrid composite with a ceramic portion of more than 73 % micro-fine ceramic. The composition supported by a filling organic polymer matrix strengthens the homogeneous structure and gives Ceramage ceramic-like properties. The material is applied for metal-supported as well as metal-free anterior and posterior restorations. -

The STAR ST Preshaded zirconia blank is non-toxic and non-radioactive with excellent biological properties, teeth color is like the real teeth with good permeability and aesthetics. It is with high strength, good toughness and excellent wear resistance, Star ST pre-shaded zirconia blank is the raw material with excellent property for making crowns.

The STAR ST Preshaded zirconia blank is non-toxic and non-radioactive with excellent biological properties, teeth color is like the real teeth with good permeability and aesthetics. It is with high strength, good toughness and excellent wear resistance, Star ST pre-shaded zirconia blank is the raw material with excellent property for making crowns. -

The zirconia blank is non-toxic and non-radioactive with excellent biological properties, teeth color is like the real teeth with good permeability and aesthetics. It is with high strength, good toughness and excellent wear resistance, STAR Sht pre-shaded zirconia blank is the raw material with excellent property for making crowns.

The zirconia blank is non-toxic and non-radioactive with excellent biological properties, teeth color is like the real teeth with good permeability and aesthetics. It is with high strength, good toughness and excellent wear resistance, STAR Sht pre-shaded zirconia blank is the raw material with excellent property for making crowns. -

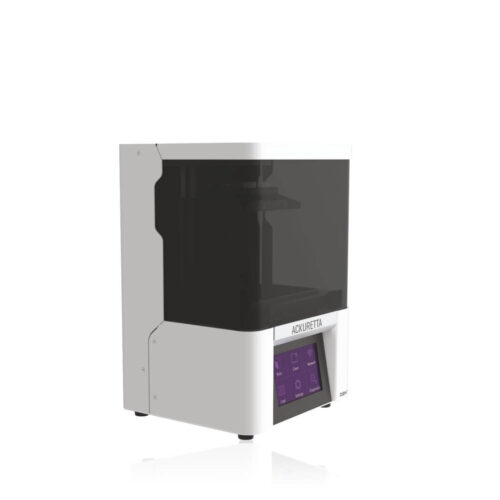

DENTIQ is a highly precise chairside 3D printer designed to provide an intuitive experience for every type of user. It offers a simple learning curve for beginners while providing the finer accuracy and consistency professionals desire. Remote diagnostics for machine repair, easy component replacement, built-in clean vat function, and warranty confidence makes owning DENTIQ effortless and rewarding. + Auto-calibration and 100+ precalibrated materials. + Plug & play, ready to use out of the box + 47-micron pixels finer accuracy and consistency + Ideal for chairside use and same-day dentistry + Premium ownership experience after purchase

DENTIQ is a highly precise chairside 3D printer designed to provide an intuitive experience for every type of user. It offers a simple learning curve for beginners while providing the finer accuracy and consistency professionals desire. Remote diagnostics for machine repair, easy component replacement, built-in clean vat function, and warranty confidence makes owning DENTIQ effortless and rewarding. + Auto-calibration and 100+ precalibrated materials. + Plug & play, ready to use out of the box + 47-micron pixels finer accuracy and consistency + Ideal for chairside use and same-day dentistry + Premium ownership experience after purchase -

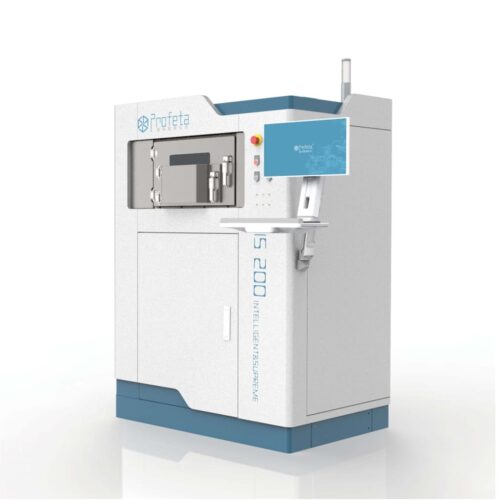

- High-end machine with advanced algorithm and components brings the fastest printing speed (4.5-5.5hrs for 400 copings/36 RPD frames).

- The building volume (250*180*70mm) brings the highest volume per batch and reduces times of operations by 50%.

- The highest powder utilization (500-600 copings or 50-60 RPD frames/kg of powder).