-

Dual Mode Machine For Easy Powder Switching

Dual Mode Machine For Easy Powder Switching- Building Volume120*70mm,130 copings/batch, 10-12 RPD frames/batch, 130 copings/3.5-4.5 hours, 10 RPD frames/3-3.5 hours.

- Dual-mode printer supports Cobalt-Chromium and Titanium, and the switching time is only 45 minutes.

- Easy to start with Cobalt-Chromium mode and be able to upgrade to dual-mode later on.

- Equipped with glove box and built-in cleaner to implement closed powder cleaning and to avoid harmful dust.

- Proven stability in domestic and global market.

-

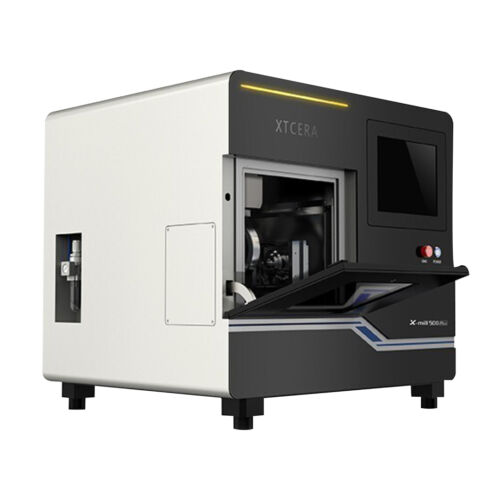

The industry’s best dental mill just got better with an all-new redesigned, upgraded spindle with 1.9× the gripping power for increased milling efficiency, expanded tool and material capabilities, and Intelligent Tool Control (ITC) • Precision 5-axis milling of zirconia, wax, PMMA, composite resin, glass fiber reinforced resin, pre-sintered chromium cobalt, and more • 15-station Automatic Tool Control and Intelligent Tool Control for uninterrupted milling operation

The industry’s best dental mill just got better with an all-new redesigned, upgraded spindle with 1.9× the gripping power for increased milling efficiency, expanded tool and material capabilities, and Intelligent Tool Control (ITC) • Precision 5-axis milling of zirconia, wax, PMMA, composite resin, glass fiber reinforced resin, pre-sintered chromium cobalt, and more • 15-station Automatic Tool Control and Intelligent Tool Control for uninterrupted milling operation